|

designs and manufacturers quality thermocouples, RTDs and temperature sensors supplying the process control industry.

Our specialty is providing custom tailored process control temperature sensing solutions to meet your industries specialized needs; quickly, and cost effectively.

We worked with several OEMs supplying the process industry with a variety of thermocouples, thermocouple assembles and RTDs used at semiconductor fabrication, mining, chemical manufacturing, and metal processing.

|

|

|

|

Products | About Us | Request A Quote | Industries | Resources | Contact | Home

Copyright 2012 C-Temp Inc. | All Right Reserved

|

|

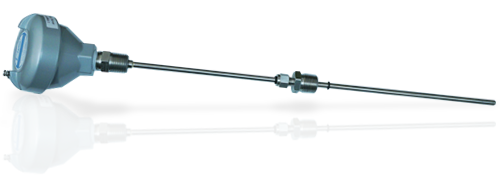

PROCESS CONTROL THERMOCOUPLE

|

Process control thermocouples have applications in any manufacturing or fabrication processes requiring some type of temperature control. One of several industries that require tight temperature control is the semiconductor wafer fabrication. The gases used in the wafer process demand uniform heating of those supply lines. When lines are heated unevenly, cold spots emerge and condensation is produced which contaminate the process. This requires expensive tool downtime. If hot spots occur in the lines, the gas composition breaks down which results in production yields being diminished. The tools that manufacture of the actual wafers require uniform temperature controls. The same controls are necessary for the manufacturing of solar and display panels. Applying precision heater circuits utilizing process control thermocouple for thick film fabrication applications is beneficial in reducing the overall weight of the thermocouple assembly.

Like the semiconductor fabrication industry, chemical manufacturing requires precise temperature control and optimum chemical mixture. A new and emerging specialty category of the chemical industry is fuel cells. Each aspect of research, development or manufacturing requires precision measurements for temperature control and accurate fluid handling to maximize the fuel cell operation. The most important and complex task is the control of gases. This can be handled by a Thermal Mass Flow Controller (TMFC). The thermal mass flow controller offers the best response time, turndown capacity and accuracy. The TMFC is connected to upstream and downstream temperature sensors. The temperature sensor may be a thermocouple or RTD for external contact applications or thermowell type for internal, direct gas contact.

|

|

PROCESS CONTROL RTDs

|

Process control RTDs (“Resistance Temperature Detectors”) are a good temperature sensor type for manufacturing or fabrication applications. RTDs are very suitable for semiconductor wafer processing fabrication because they offer accuracy and stability. The gases used in semiconductor wafer fabrication require the gas supply lines to be uniformly heated to optimize gas flow. If the supply lines are heated unevenly, cold areas occur which produce condensation which can contaminate the integrity of the gas. If hot spots occur in the lines, the gas composition can break down which results in diminished production yields. The importance of uniform temperature control by using RTDs as the primary temperature sensor can be critical. The same issues of temperature control exist for the manufacturing of solar and display panels. Applying precision heater circuits utilizing RTDs as the primary temp sensor for thick film fabrication applications is will help reduce the overall weight while keeping the cost of the process control RTD assembly down.

Chemical manufacturing, like the semiconductor fabrication industry, requires precise temperature control and optimum chemical mixture. An upcoming and growing specialty category, new to the chemical industry is fuel cells. The fuel cell industry is very similar to semiconductor wafer fabrication because it requires precision measurements for temperature control and accurate fluid handling to maximize the fuel cell operation. As with wafer fabrication, the control of gases is one of the most important and complex task in the development or the manufacturing of a fuel cell. In general, most engineers prefer using a Thermal Mass Flow Controller (TMFC). The thermal mass flow controller provides the best accuracy, response time and flow capacity. The TMFC works by connecting to an upstream and downstream temperature sensor. Depending on the application, the temperature sensor for external contact type may be a thermocouple or RTD, any internal, direct gas contact would use a thermowell.

|

|

PROCESS CONTROL TEMPERATURE SENSOR

|

C-Temp International has been designing and manufacturing process control temperature sensor since 1981. For over 31 years, the company has been building temperature sensors for a variety of process control industries and varying applications from component level units to multi-functional, custom assemblies. Our specialization is custom temperature sensor assemblies that include the use of thermocouples, RTDs (“Resistance Temperature Detectors”), thermistors, and thermowells. We manufacturer customer’s designs by building from print or we design and build from spec. We build our process control temperature sensor in an ISO9001 facility to meet the highest quality standards. We primarily manufacture in the United States, however, we have contract manufacturing in China to support high volume requirments.

|

|

|