|

is a thermistor assembly manufacturer designing and building NTC Element or PTC Element type assemblies. We pledge to provide quality products and responsive customer service. is a thermistor assembly manufacturer designing and building NTC Element or PTC Element type assemblies. We pledge to provide quality products and responsive customer service.

Our objective is to make it easy for you to do business with us.

We build custom thermistor assemblies.

Give us your drawing, SCD or specification. Our sales team will respond with a quotation.

If you need any assistance in designing a thermistor assembly, C-Temp provides complementary engineering services.

Responsive, precision and quality in everything we build.

|

|

|

|

Products | About Us | Request A Quote | Industries | Resources | Contact | Home

Copyright 2012 C-Temp Inc. | All Right Reserved

|

|

THERMISTOR ASSEMBLIES

|

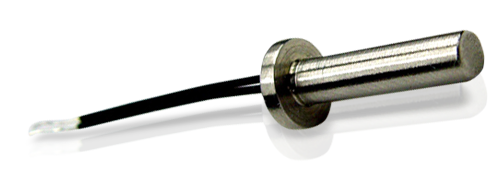

A thermistor assembly is a cable or wire connected to a thermistor. The cable or wire provides the transmission of the output from the thermistor. Thermistors are thermally sensitive devices that measure temperature through a change in electrical resistance when subjected to variations of heat. Thermistors are not “self-heating” devices, therefore, they will absorb the temperature of the environment through radiation or; if attached, by conduction through a surface. The most important characteristic of a thermistor is its extremely high temperature coefficient of resistance. This provides very predictable resistance vs. temperature calculations which gives it its precise measurement characteristics.

Thermistor assemblies are used in a wide variety of applications. The primary uses are in temperature control, measurement and analysis. They are a favorite in industrial applications because, in addition to thermistors precision measuring qualities, thermistors offer long term stability because they do not fluctuate or lose their tight tolerance over time. Thermistor assembles can be used in applications that have wide temperature variations. Depending on the control range, special thermistors can operate in environments from -100° to +600°F. Another major advantage of a thermistor is its size relative to its capacity. They can be very small and flat which make them ideal for tight spaces. Thermistor assembles are ideal because they are versatile, accurate and inexpensive.

|

|

NTC ELEMENT ASSEMBLIES

|

NTC Element Assemblies (“Negative Temperature Coefficient’) are thermistor assembles that display a decrease in electrical resistance when subjected to a rise in radiated or conducted temperature. Thermistors are ceramic semiconductors coated with a phenolic or epoxy material that protects them from environmental elements. The most common types of thermistors are chip, disc and glass bead arrangements. Depending on the materials and methods of fabrication, NTC thermistors are generally used in the temperature range of -50°C to 150°C and for some glass-encapsulated types, up to 300°C. Because of NTC thermistor's relatively large change in resistance vs. temperature providing an order of magnitude greater sensitivity or signal response (around -3%/°C to -6%/°C ) making them an ideal choice for applications under 200°C.

The most important aspect of the NTC thermistors assembly is the NTC thermistor element. Thermistor elements are made from various compositions of the metal oxides which include manganese, nickel, cobalt, copper, and/or iron. Producing NTC elements require certain basic processes. For most general ceramics, the first step is the formulation and composition of the metal oxide powders. Once the powder is prepped, it is milled and blended with a binder. The material is then formed into a "green" body and goes through a heat-treating process to produce the ceramic material. For discs and chips, the material may have electrical contacts attached. For discrete type components, the material will embed wire leads. At this point, the protective coating will be added.

|

|

PTC ELEMENT ASSEMBLIES

|

PTC Element Assemblies (“Positive Temperature Coefficient’) are thermistor assemblies that display a rise in electrical resistance when subjected to a rise in radiated or conducted temperature. Like NTC, PTC type thermistors are ceramic semiconductors coated with a phenolic or epoxy material that protects them from environmental elements. The most common types of PTC or NTC thermistors are chip, disc and glass bead arrangements. Depending on the materials and methods of fabrication, PTC thermistors are generally used in the temperature range of -50°C to 150°C and for some glass-encapsulated types, up to 300°C. Regardless of the positive or negative temperature coefficient, the thermistor's relatively large change in resistance vs. temperature providing an order of magnitude greater sensitivity or signal response (around -3%/°C to -6%/°C ) making them an ideal choice for applications under 200°C.

Like the NTC, the most important aspect of the PTC thermistors assembly is the PTC thermistor element. Thermistor elements are made from various compositions of the metal oxides which include manganese, nickel, cobalt, copper, and/or iron. Producing NTC elements require certain basic processes. For most general ceramics, the first step is the formulation and composition of the metal oxide powders. Once the powder is prepped, it is milled and blended with a binder. The material is then formed into a "green" body and goes through a heat-treating process to produce the ceramic material. For discs and chips, the material may have electrical contacts attached. For discrete type components, the material will embed wire leads. At this point, the protective coating will be incorporated.

|

|

|