designs and manufacturers thermocouples and assembles utilizing all standard base metal types. We serve a variety of industries and have experiences with diverse applications for over 30 years. We want to earn your business by providing exceptional service and by delivering quality products.

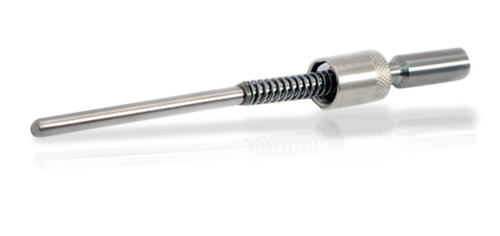

Our area of expertise is turnkey thermocouple assemblies – designing the assembly from scratch or building it from a drawing, we want to manufacture the base metal thermocouple assembly.

Let us help with the design, especially, if it is a custom or specialized requirement, we have engineering ready to assist in any of your thermocouple needs.

Responsive, accurate and quality in everything we build. Contact us for a free quote.

Click on the following icon for additional details: