|

C-Temp International is a designing and building products and since 1981. Our objective is to earn your business the old fashion way through quality products and exceptional customer service.

Our principal discipline is building thermowell assemblies.

We are very familiar with responding to a drawing, SCD or specification.

C-Temp International also supplies separate thermowell components from sensor elements, wires, all types of connectors, housings, and mounting options.

Responsive, precision and quality in everything we build. Call us for a free quote.

|

|

|

|

Products | About Us | Request A Quote | Industries | Resources | Contact | Home

Copyright 2012 C-Temp Inc. | All Right Reserved

|

|

THERMOWELL MANUFACTURER

|

Headquartered in Gardena, California, C-Temp International was formed in 1981 as a thermowell manufacturer to serve the HVAC, industrial, food service, process control, and military equipment OEMs in need of accurate, reliable and affordable customized RTD (“Resistance Temperature Detector”) solutions. Over the years, we have been improving our thermowell manufacturing processes to provide high quality, world class products. Today, C-Temp International is dedicated to evolving to advance our manufacturing standard and our thermowell production capabilities for the benefit of our end users and major OEMs. We’ve delivered thousands of thermowell and thermowell assemblies as industry standard configurations and custom designed units.

Other areas of our thermowell manufacturing expertise are thermowell accessory products such as the temperature elements, wire, connectors, and fittings. Many of our thermowell measurement products are engineered into equipment at the world's leading instrumentation, process control and semiconductor companies. C-Temp International’s thermowell manufacturer’s proficiency includes advanced ultra-high temperature materials utilization and metallurgical processes. Our capability extends to a full range of state-of-the-art products for flexible interconnect needs. We deliver customized elements, probes, wire assemblies with specialty terminations to suit any particular industrial needs one may have. Not only do we manufacturer thermowells, but we offer a full range of custom design services to provide you with the benefit of our knowledge and experience.

|

|

THERMOWELL ASSEMBLIES

|

C-Temp International’s forte is Thermowell Assemblies. We have a great deal of experience and are very proficient at manufacturing (i.e., build to print or build to spec) for those who have the ability to design their own resistance temperature detectors in-house and are seeking a veteran Thermowell manufacturer to build it. By utilizing our production capabilities, you benefit by using our skilled assembly technicians and established suppliers to build your resistance temperature detectors. All of our years of manufacturing experience and quality control go into the assembly of your product. Our production team will adhere to high quality manufacturing standards and comply to our strict assembly guidelines. After your custom thermowell is assembled, we’ll provide final inspection and test per our quality criteria or yours. Our team will do it right, on-time and on budget.

All of our custom thermowell and thermowell assemblies are tested for adequate insulation resistance. All cable is certified and checked for ANSI limits of error conformance by standard lot sampling in our quality control laboratory, which is certified traceable to the NIST. Finished assembly certified traceable calibration is available at time of order.

|

|

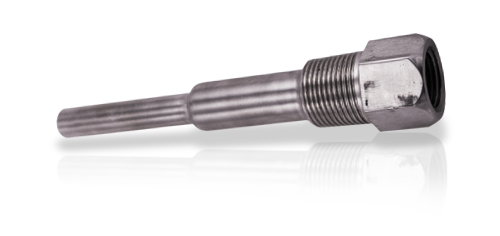

THERMOWELLS

|

A thermowell is an enclosure or housing used to protect a temperature sensor (RTD or thermocouple) from exposure to hazardous materials or extreme environments. The American Society for Testing and Materials (ASTM) defines a thermowell as a “closed-ended tube designed for insertion of a temperature-sensing element, and provided means for a pressure-tight attachment to a vessel.” Essentially, a thermowell is made from solid metal bar stocked, machined out to allow the temperature sensor placement within its confines. They can be either an open or fully enclosed construction.

The most common types of thermocouples are flanged, socket or threaded and are classified based on their mounting type. The flanged can be bolted or welded on into position. The socket type is welded into position and the threaded style will be screwed into position. For each of these attachment methods, each must be connected to maintain a pressure tight seal to prevent any leakage.

There are 6 basic components of a Thermowell:

- Bore size: This is the inside diameter of the Thermowell. Typical bore sizes are .260" and .385". These sizes are intended to accept a quarter or three eights inch diameter sensor.

- Immersion Length: Thermowell immersion lengths are often called the "U" length which is the measurement of the Thermowell from the bottom of the process connection to the top portion of the Thermowell.

- Process Connections: This is the manner in which a Thermowell is inserted and connected into a process referring to the attachment of the element. The most popular are threaded, socket weld, and flanged connections.

- Shank Construction: This is immersion portion (shank) of the construction. The majority fall under three categories: straight, step or tapered. The straight shank is the same size all along the immersion length. The step shank has a larger outer diameter at the end of the immersion length and the tapered version decreases gradually along the immersion length.

- Lagging Extension Length: The lagging extension commonly referred to as the “T” length is located on the cold side of the process connection and is usually an extension of the hex length

- Q Dimension: This is the outside dimension of the Thermowell shank and is densest part because the outside surface area is exposed to the hazardous materials of the process.

|

|

|